This page is a sub-page of our page on The EE(S+O+C)(M+O+P) Model.

///////

The EE(S+O+C)(M+O+P) model:

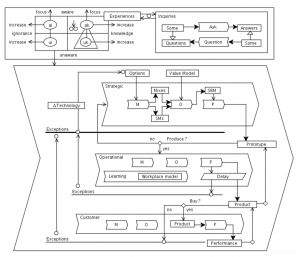

The EE(S+O+C)(M+O+P) model represents an attempt to model a larger context within which the EMEMO model and the TELLME platform can be positioned. It has its roots in PROLEARN D5.3 and D1.10, and has taken on increased importance in TELLME due to the feedback of the reviewers.

The PLPF (Professional Learning Process Framework) of PROLEARN D1.10 delinearized the traditional SECI-model of Nonaka by “breaking out” the EI loop of Externalization and Internalization) which goes on all the time. The activities (and attention) of this loop were then distributed across the parallel processes of C and S (Combination and Socialization) but which could just as well be interpreted as explicit and tacit, formal and informal, conscious and subconscious, etc, …).

In a similar way, the EE(S+O+C)(M+O+P) model delinearizes the EMEMO model by breaking out the EE loop, which goes on all the time, and which guides and controls the other processes by distributing its corresponding attention/comprehension across the (Strategic + Operational + Customer) activities of a company X. Moreover, each of these levels are then addressed by a (Mix+Optimize+P) process, where the P stands for Prototype at the Strategic level, Produce at the Operational level, and Perform at the Customer level of company X.

The Ericsson AXE10 Delay:

Prior to its introduction in 1976 the Ericsson AXE10 switchboard was delayed, due to a delay in the production of one of its key components. This raised an exception at the operational level (in the “Produce” stage of the M+O+P process. This “delay-exception” was then mapped to the strategic level and turned into an opportunity for Ericsson to review the options for substituting the delayed component with something better.

Due to the rapid advance of digital technology – represented by the box ∆Technology in Figure 7, Ericsson decided to delay a bit further and redesign the switchboard in order to replace the delayed component with a digital version that had a much larger capacity. When the AXE10 came on the market a year later than initially planned, it “slaughtered” the competition by displaying vastly superior performance. In fact, the AXE10 switchboard became one of the most successful products in the history of Ericsson.

The Ericsson supply chain expressed in business algebra:

Using business algebra, the supply chain of a company can be modeled as a a sequence of relational threads (= chains of relationships).

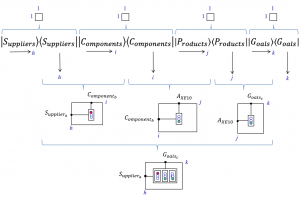

If we consider \, S_{uppliers}, C_{omponents}, P_{roducts}, \text{and } G_{oals} \, , we can write the supply chain as the matrix product:

\left| S_{uppliers} \right> \left< S_{uppliers} \right| \left| C_{omponents} \right> \left< C_{omponents} \right| \left| P_{roducts} \right> \left< P_{roducts} \right| \left| G_{oals} \right> \left< G_{oals} \right| \,

Due to the associativity of the underlying matrix algebra, this supply chain can be considered, for example, as the product of the following four 1×1 matrices:

(\left| S_{uppliers} \right> \left< S_{uppliers} \right|) \, (\left| C_{omponents} \right> \left< C_{omponents} \right|) \, (\left| P_{roducts} \right> \left< P_{roducts} \right|) \, (\left| G_{oals} \right> \left< G_{oals} \right|) \,

However, the same product can also be considered, for example, as the product of the following five factors:

\left| S_{uppliers} \right> \, (\left< S_{uppliers} \right| \left| C_{omponents} \right>) \, (\left< C_{omponents} \right| \left| P_{roducts} \right>) \, (\left< P_{roducts} \right| \left| G_{oals} \right>) \, \left< G_{oals} \right| \,

of which the left-most factor is a row vector, the right-most factor is a column vector, and the middle three factors are dyadic matrices of compatible formats for matrix multiplication.

These two ways of interpreting the Ericsson relational supply chain are depicted in the figure below

The top-level “traffic light” products of the Ericsson supply chain paths:

This figure shows the top-level Ericsson supply chain product as a formal matrix product of traffic lights, each one dynamically controlled by some form of change management process. In this way a company can have dynamic control over each separate path and manage its interactions with others more effectively and efficiently. As described above, one of the components, called \, {C_{omponent}}_b \, in the figure, of the (at that time) soon-to-be-released switchboard was red-flagged for delay by the corresponding supplier, called \, {S_{upplier}}_a \, . This red flag is reflected in the switch to red of the left-most factor of the sequence of traffic lights displayed at the bottom of the figure.

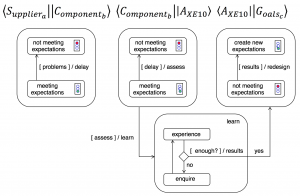

The figure below shows the matrix product of the three relational matrices

\, (\left< {S_{upplier}}_a \right| \left| {C_{omponent}}_b \right>) \, (\left< {C_{omponent}}_b \right| \left| A_{XE10} \right>) \, (\left< A_{XE10} \right| \left| {G_{oal}}_c \right>) \,at the next level of detail. The traffic lights have been expanded to state diagrams that model not only that – but also under what conditions – the switch from green to red is occurring.

The next-to-top level diagram product of the problematic supply chain path:

As seen in this figure, the dynamic interactions are handled by message passing between state diagrams in accordance with the Unified Modeling Language.

The leftmost factor diagram is owned by \, {S_{upplier}}_a \, and, when the [problems] with \, {C_{omponent}}_b \, occur, \, {S_{upplier}}_a \, changes its status regarding \, {C_{omponent}}_b \, of \, A_{XE10} \, by transiting from the state “meeting expectations” to the state “not meeting expectations”. Moreover, \, {S_{upplier}}_a \, announces a delay of this component of \, A_{XE10} \, to Ericsson by sending a “delay” message, which is indicated by the / symbol following the [problems] indicator in the leftmost factor diagram.

This delay message is picked up by the middle factor diagram (which is owned by Ericsson) and causes a transition from the state “meeting expectations” to the state “not meeting expectations” regarding the launching of \, A_{XE10} \, . This transition, in turn, generates an “assess” message that initiates a learn loop consisting of “enquire” and “experience” – in order to figure out how best to handle the new situation.

When [enough] has been learned in order to carry out the assessment of the available options, the results of this learn loop are passed to the right-most factor diagram, which relates the \, A_{XE10} \, to the \, {G_{oal}}_c \, for it. These results in turn trigger a “human transition” from “not meeting expectations” to “create new expectations,” a transition that sends a “redesign” message (not shown in the figure), which is presumably picked up by the corresponding Ericsson R&D teams – the teams that created the game-changing digital switchboard that was released about a year later (1976).

///////

Hi there I am so glad I found your website, I really found you by mistake, while I was researching on Yahoo for something else, Regardless I am here now and would just like to say thank you for a remarkable post and a all round exciting blog (I also love the theme/design), I don’t have time to read through it all at the minute but I have book-marked it and also included your RSS feeds, so when I have time I will be back to read much more, Please do keep up the superb job.

It’s amazing in favor of me to have a web site, which is valuable for my know-how. thanks admin.

WOW just what I was searching for. Came here by searching for keyword.

We are a group of volunteers and starting a brand new scheme in our community. Your web site offered us with useful information to work on. You’ve done a formidable task and our entire community will be thankful to you.

This is very interesting, You’re an overly professional blogger. I’ve joined your feed and stay up for searching for more of your fantastic post. Also, I’ve shared your web site in my social networks.

Please let me know if you’re looking for a writer for your weblog. You have some really good articles and I feel I would be a good asset. If you ever want to take some of the load off, I’d love to write some articles for your blog in exchange for a link back to mine. Please shoot me an email if interested. Cheers!|

I want to to thank you for this wonderful read!! I certainly loved every bit of it. I’ve got you saved as a favorite to check out new things you post…

Because the admin of this web site is working, no doubt very shortly it will be renowned, due to its quality contents.|

Why users still make use of to read news papers when in this technological globe everything is existing on net?

Good web site you have got here.. It’s hard to find excellent writing like yours nowadays. I honestly appreciate people like you! Take care!!

Good day very cool blog!! Guy .. Beautiful .. Wonderful .. I’ll bookmark your site and take the feeds additionally? I am glad to find numerous helpful information here within the submit, we need work out more techniques on this regard, thanks for sharing . . . . . .